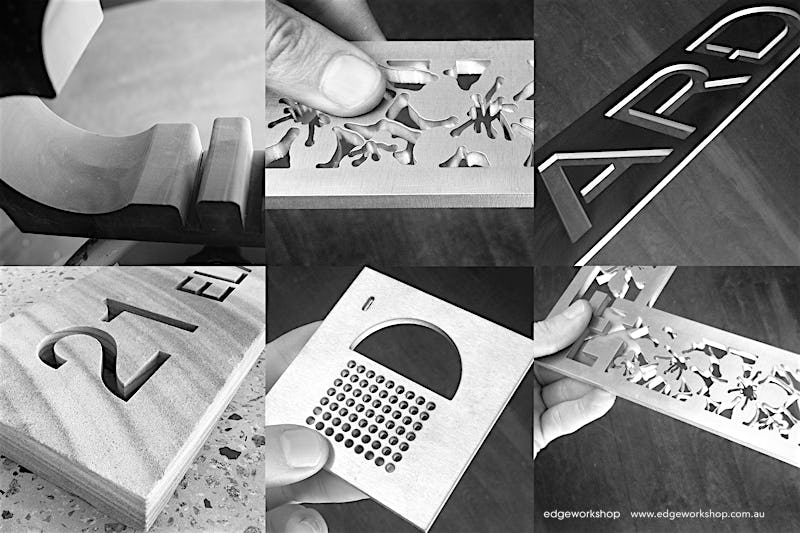

Water Jet Cutting

At Edgeworkshop our 21st century tools include two magnificent highly accurate and efficient Australian built 'Techni' water jet machines. With these machines at our disposal we can cut metals and alloys, plastics, rubbers, stone, ceramics and glass. We are conveniently located in Osborne Park, Perth and welcome jobs of all sizes.

General Cutting

- One off jobs

- Trimming and hole cutting of tiles, slabs, bench tops and basins

- Profile cutting for artists, designers and engineers

File Preparation

- Artwork Translation/Reproduction

- Design Concept Development

Material Supply

- Aluminium

- Stainless steel

- Mild steel

About Water Jet Cutting

Water jet cutting uses a stream of ultra high-pressure water (66,000 psi) and abrasive particles to machine a large array of materials, including heat-sensitive, delicate or very hard. The resulting cut is both clean and accurate to a tolerance of 0.025mm. Unlike Laser or Plasma, the cold stream does not create hardened edges. Minor burr removal is generally the only post cutting clean up required. Many materials cut well using the water jet, among these are all metals and alloys, plastic, rubber, stone, ceramics and glass. Controlled head run rate, allows for cutting items up to 200mm thick. Vertical run out is almost non existent at optimum speed.

Versatility, Accuracy & Edge Quality

- Thickness

- up to 200mm

- Tolerance

- 0.025mm

- Kerf

- < 1mm